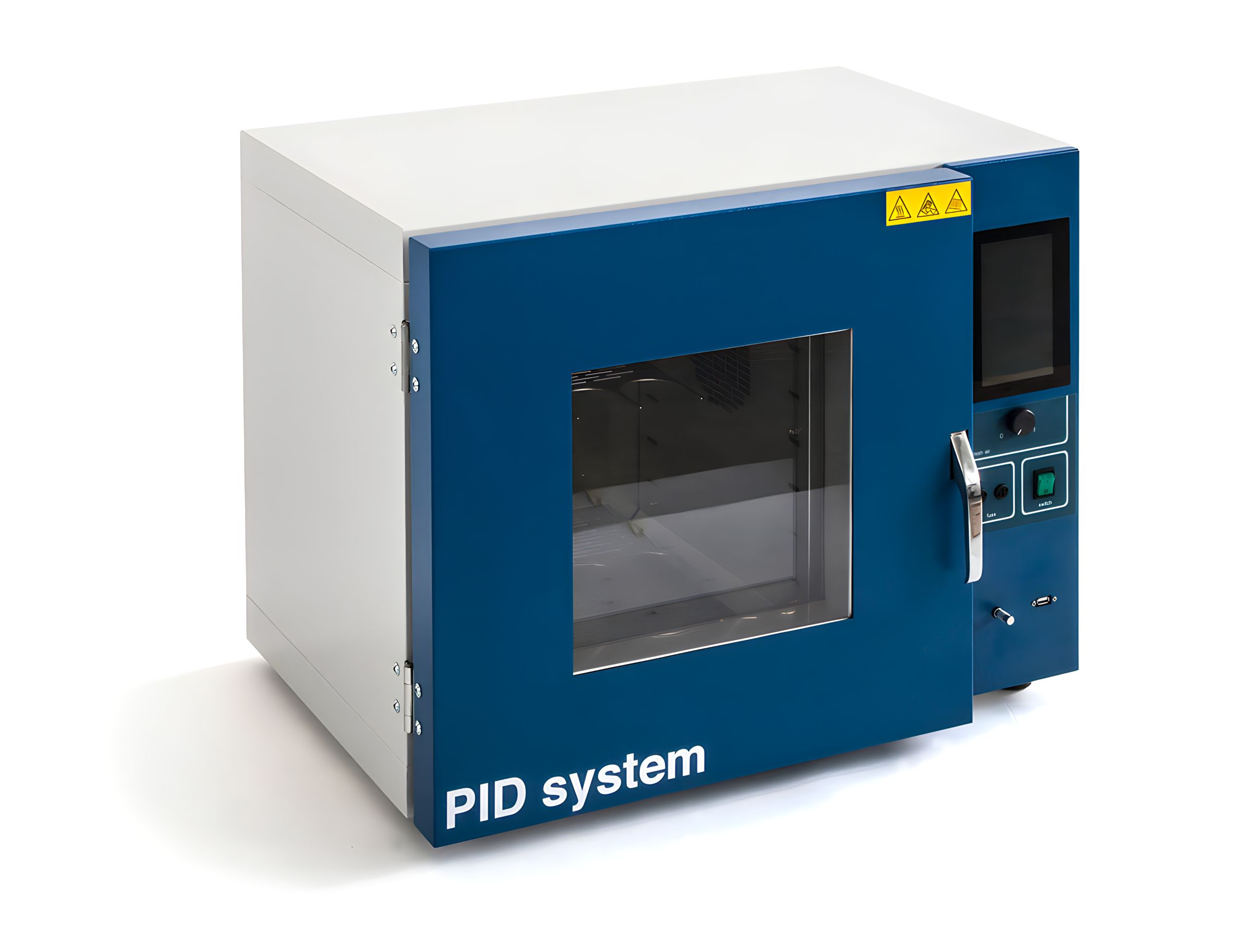

Determination of the evaporation loss of lubricating oils (particularly engine oils).Procedure A uses the Noack evaporative tester equipment.Procedure B uses the automated non-Woods metal Noack evaporative apparatus.

A quantity of 65 grams of sample is heated to a specific temperature and maintained for 1 hour while it is enclosed in a crucible, the crucible’s cover is shaped to allow a constant vacuum of -2 mbar to remove from the crucible the evaporating portion of the sample. At the end of the test, the sample is cooled and then reweighted: the difference, reported in percentage, represent the sample’s Evaporation Loss by the Noack Method. Method A: bath is controlled at 250°C. Method B: the sample is controlled at 245.2°C.

Flash Point on petroleum products, gas oils, fuel oils, lubricants, biodiesel. Suitable for flash point detection on different substances, waste materials, solvents…

The sample is heated and stirred at specified rates, using one of three defined procedures (A, B, or C). An ignition source is directed into the test cup at regular intervals with simultaneous interruption of the stirring, until a flash is detected.

.jpg)

.jpg)

Flash Point on petroleum products, gas oils, fuel oils, lubricants, biodiesel. Suitable for flash point detection on different substances, waste materials, solvents…

Flash Point on petroleum products, gas oils, fuel oils, lubricants, biodiesel. Suitable for flash point detection on different substances, waste materials, solvents…

.jpg)

.jpg)

Flash and Fire Point on petroleum products, gas oils, fuel oils, lubricants. Suitable for flash and fire point detection on different substances and waste materials, having a flash point over 79°C.

The sample is warmed up according the methods. When the sample reaches the selected test temperature, the flame is passed automatically above the sample. When the flash point is reached, the detection is done by an ionisation detector. For fire point detection, the sample continues to be heated until permanent flame is detected by the second PT100 probe, then the auto extinguisher will be placed on the top of the test cup.

Flash and Fire Point on petroleum products, gas oils, fuel oils, lubricants. Suitable for flash and fire point detection on different substances and waste materials, having a flash point over 79°C.

.jpg)

.jpg)

Flash and Fire Point on petroleum products, gas oils, fuel oils, lubricants. Suitable for flash and fire point detection on different substances and waste materials, having a flash point over 79°C.

The sample is cooled down according to the methods while the clouds appearance is observed on the silver bottom of the test jar by means of an optical sensor. The measurement is done by reflection on the silver bottom of the test jar via a fast light detector. The signal from light detector is traded by the LabLink software. The dynamic measurement is performed regardless of the sample’s colour.

According to the methods, the sample is cooled down at a specified rate and, at the prescribed temperature intervals, the mechanical arm of the analyser lifts the test jar from the cooling jacket and tilts it in order to bring it in horizontal position to test the flow of the product. The sample movement is detected by the thermal probes (PT100 detection) placed above the sample surface which react if touched by the cooled sample.

.jpg)

.jpg)

This test method is intended for use on any petroleum product. Suitable for black specimens, cylinder stock, and non-distillate fuel oil and for testing the fluidity of a residual fuel oil at a specified temperature is described.

Foaming characteristics of lubricating oils: this test method covers the determination of the foaming characteristics of lubricating oils at 24°C and 93.5°C. Means of empirically rating the foaming tendency and the stability of the foam are described.

.jpg)

Foaming characteristics of lubricating oils: this test method covers the determination of the foaming characteristics of lubricating oils at 24°C and 93.5°C. Means of empirically rating the foaming tendency and the stability of the foam are described.

.jpg)

This test method covers the atmospheric distillation of petroleum products using a laboratory batch distillation unit to determine quantitatively the boiling range characteristics of such products as natural gasolines, light and middle distillates, automotive spark-ignition engine fuels, aviation gasolines, aviation turbine fuels, 1-D and 2-D regular and low sulphur diesel fuels, special petroleum spirits, naphthas, white spirits, kerosines, and Grades 1 and 2 burner fuels. The test method is designed for the analysis of distillate fuels; it is not applicable to products containing appreciable quantities of residual material.

This test method covers the atmospheric distillation of petroleum products using a laboratory batch distillation unit to determine quantitatively the boiling range characteristics of such products as natural gasolines, light and middle distillates, automotive spark-ignition engine fuels, aviation gasolines, aviation turbine fuels, 1-D and 2-D regular and low sulphur diesel fuels, special petroleum spirits, naphthas, white spirits, kerosines, and Grades 1 and 2 burner fuels. The test method is designed for the analysis of distillate fuels; it is not applicable to products containing appreciable quantities of residual material.

Manual instrument for distillation composed by:

.jpg)

This test method covers the determination of total sediment up to 0.40 % m/m for distillate fuel oils containing residual components and to 0.50 % m/m in residual fuel oils having a maximum viscosity of 55 cSt (mm2/s) at 100°C.

.jpg)

.jpg)

ASTM D525 - IP 40 - DIN 51780 - ISO 7536 - Oxidation Stability of Gasoline (Induction Period Method) This test method covers the determination of the stability of gasoline in finished form only, under accelerated oxidation conditions.

ASTM D873 - IP 138 - DIN 51799 - Oxidation Stability of Aviation Fuels (Potential Residue Method) This test method covers the determination of the tendency of aviation reciprocating, turbine, and jet engine fuels to form gum and deposits under accelerated ageing conditions.

Aniline Point and Mixed Aniline Point of Petroleum Products and Hydrocarbon Solvents. Test method E describes a procedure using an automatic apparatus suitable for the range covered by test methods A and B.

Standard Test Method for Air Release Properties of Hydrocarbon Based Oils. This test methods cover the ability of turbine, hydraulic and lubricating oils to separate entrained air.

Compact bench instrument is fully independent, equipped in standard with density measurement system, heater, temperature control system, pressure regulation and microprocessor-based control system and other devices to assure perfect performance in all range of application. Design of the instrument is very easy to use and allows even inexperienced operator to perform routine tests.

ASTM D942 - Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Pressure Vessel Method. This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test.

ASTM D2272 - Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel. This test method utilizes an oxygen-pressured vessel to evaluate the oxidation stability of new and in-service turbine oils having the same composition (base stock and additives) in the presence of water and a copper catalyst coil at 150°C.

ASTM D4742 - Standard Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT). This test method evaluates the oxidation stability of engine oils for gasoline automotive engines. This test, run at 160 °C, utilizes a high pressure reactor pressurized with oxygen along with a metal catalyst package, a fuel catalyst, and water in a partial simulation of the conditions to which an oil may be subjected in a gasoline combustion engine. This test method can be used for engine oils with viscosity in the range from 4 mm2/s (cSt) to 21 mm2/s (cSt) at 100 °C, including re-refined oils.

ASTM D7098 - Standard Test Method for Oxidation Stability of Lubricants by Thin-Film Oxygen Uptake (TFOUT) Catalyst B. This test method covers the oxidation stability of lubricants by thin-film oxygen uptake (TFOUT) Catalyst B. This test method evaluates the oxidation stability of petroleum products, and it was originally developed as a screening test to indicate whether a given re-refined base stock could be formulated for use as automotive engine oil (see Test Method D4742). The test is run at 160 °C in a pressure vessel under oxygen pressure, and the sample contains a metal catalyst package, a fuel catalyst, and water to partially simulate oil conditions in an operating engine. In addition, the test method has since been found broadly useful as an oxidation test of petroleum products.

IP 229 - Relative Oxidation Stability by Rotating Bomb of Mineral Turbine Oil (RBOT). This method covers a rapid means for estimating the oxidation stability of new turbine oils having the same composition.

His compact dimensions 35 × 38 × 41 cm and relative light weight only 25 Kg can assure an easy handling and find space above each table.

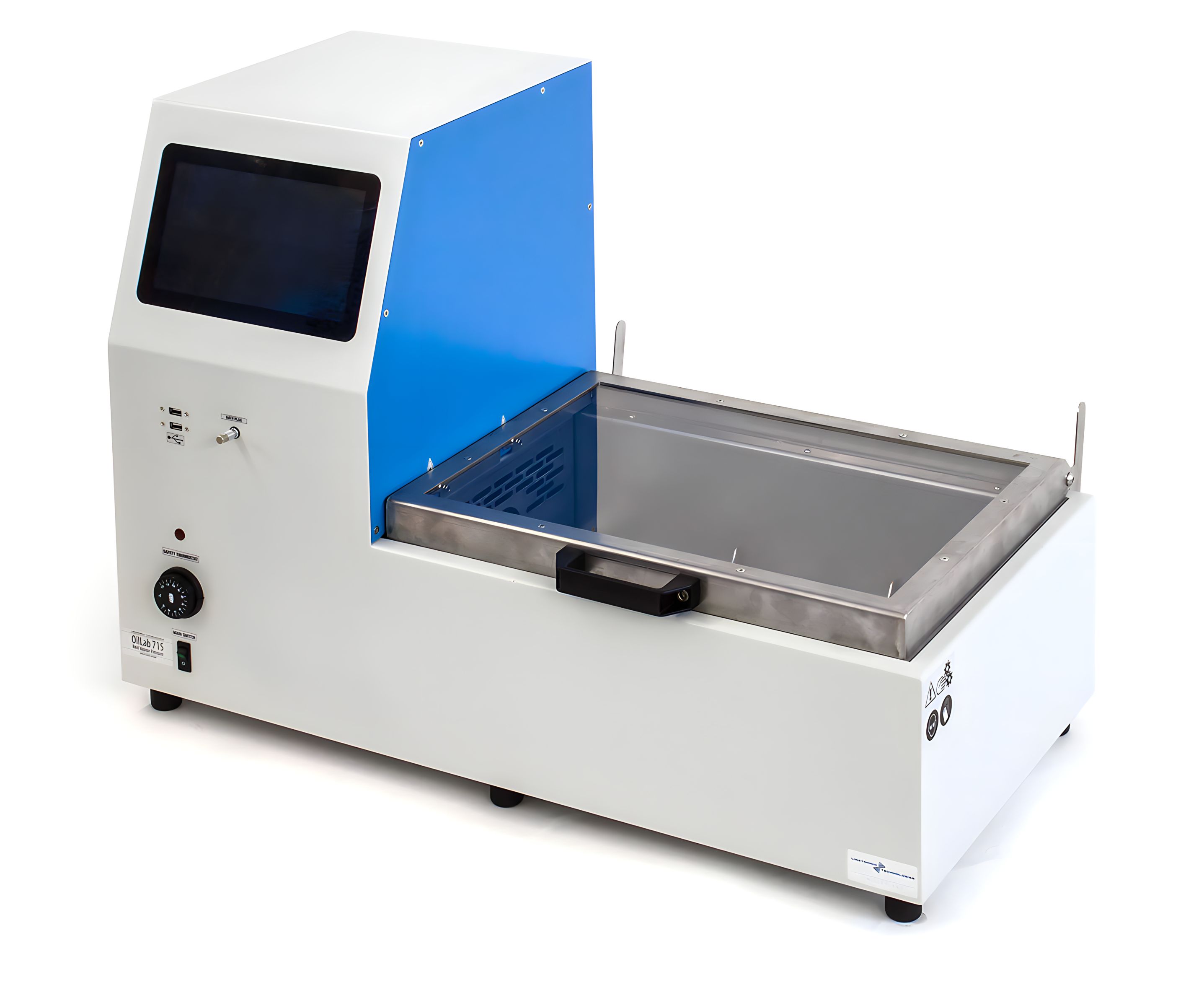

ASTM D323 - IP 69 - ISO 3007 Vapour Pressure of Petroleum Products (Reid Method) The test method covers the determination of vapour pressure of gasoline, volatile crude oil, by means of three procedures: A, B and C. The OilLab 715 grant the determination in conformity with the procedure B (horizontal bath) on petroleum products having Reid Vapour Pressures below 180 kPa (26 psi).

ASTM D4953 Standard Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends This test method covers and is applicable to gasolines and gasoline-oxygenate blends with a vapor pressure range from 35 kPa to 100 kPa (5 psi to 15 psi). This test method, a modification of Test Method D323 (Reid Method), provides two procedures to determine the vapor pressure of gasoline and gasoline-oxygenate blends.

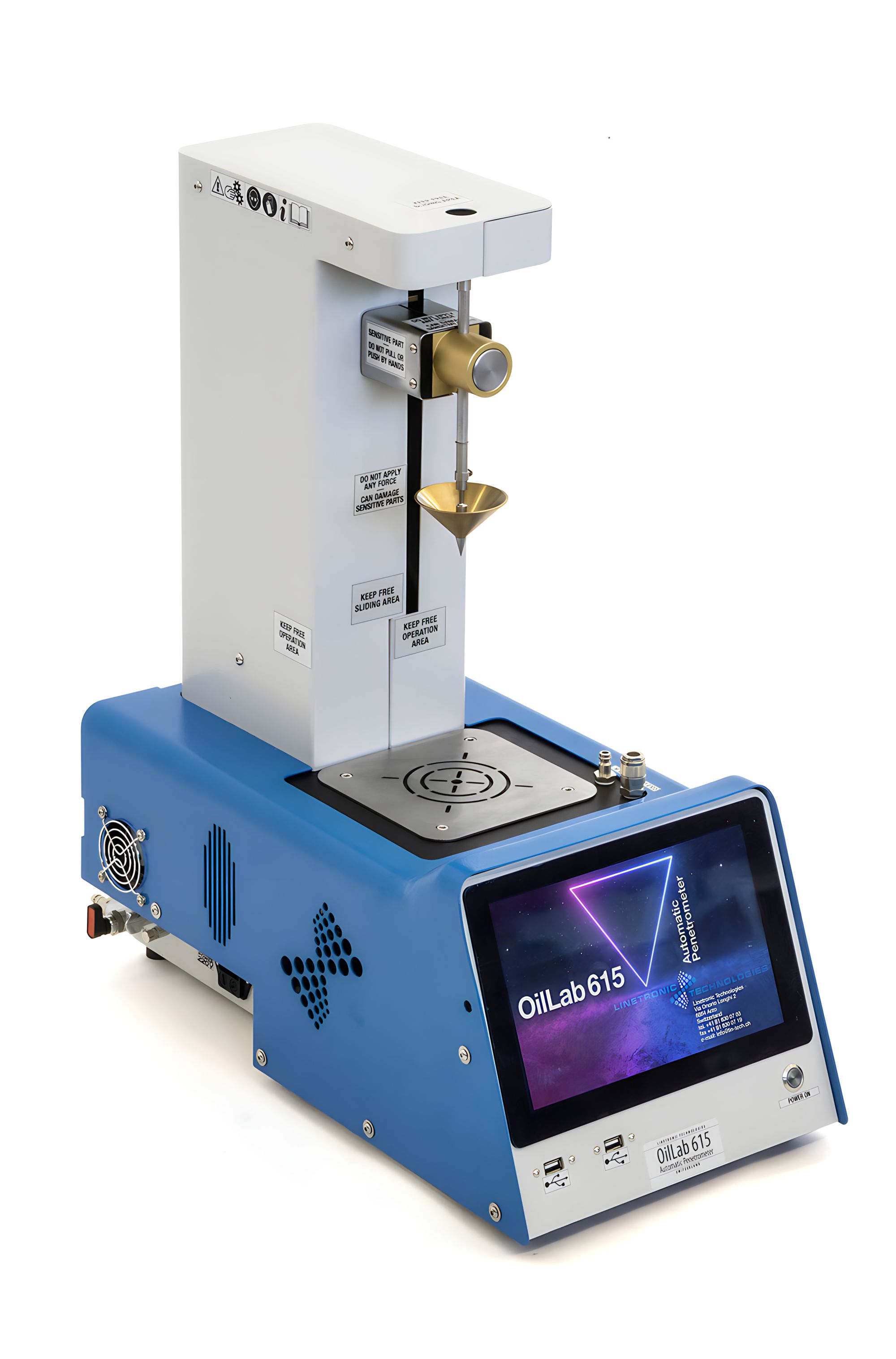

ASTM D5, IP 49, DIN 52010Penetration of bituminous material.For determination of the penetration of semi-solid and solid bituminous materials.

ASTM D217, ASTM D1403, IP 50, IP 310, DIN 51804, ISO 2137 - Cone penetration of lubricating grease. Cover four procedures for measuring the consistency of lubricating greases by the penetration of a cone of specified dimensions, mass and finish.

ASTM D937, IP 179, DIN 51580, ISO 2137 - Cone penetration of petrolatum. Covers measuring with a penetrometer the penetration of petrolatum as an empirical measure of consistency.

ASTM D1321, IP 376, DIN 51579 - Needle penetration of petroleum waxes. Covers the empirical estimation of the consistency of waxes derived from petroleum by measurement of the extent of penetration of a standard needle. This test method is applicable to waxes having a penetration of not greater than 250.

ASTM D1831 - Roll stability of lubricating grease. Covers determination of the changes in the consistency, as measurably cone penetration, of lubricating greases when worked in the roll stability test apparatus.

ASTM D2884 - Yield stress of heterogeneous propellants by cone penetration method. Covers determination of the yield stress of heterogeneous propellants, both of the gel and emulsion types, containing from 0 to 70% solid additives.

.jpg)

Digital Saybolt Viscometer ASTM D88, ASTM E 102 - 4 places

The ductility of a bituminous material is measured by the distance to which it will elongate before breaking when two ends of a briquet specimen of the material are pulled apart at a specified speed and at a specified temperature. Unless otherwise specified, the test shall be made at a temperature of 77 ± 0.9°F (25 ± 0.5°C) and with a speed of 5 cm/min ± 5.0%. At other temperatures the speed should be specified.

Ductility of Bituminous Materials Electric and Refrigerated - ASTM D113

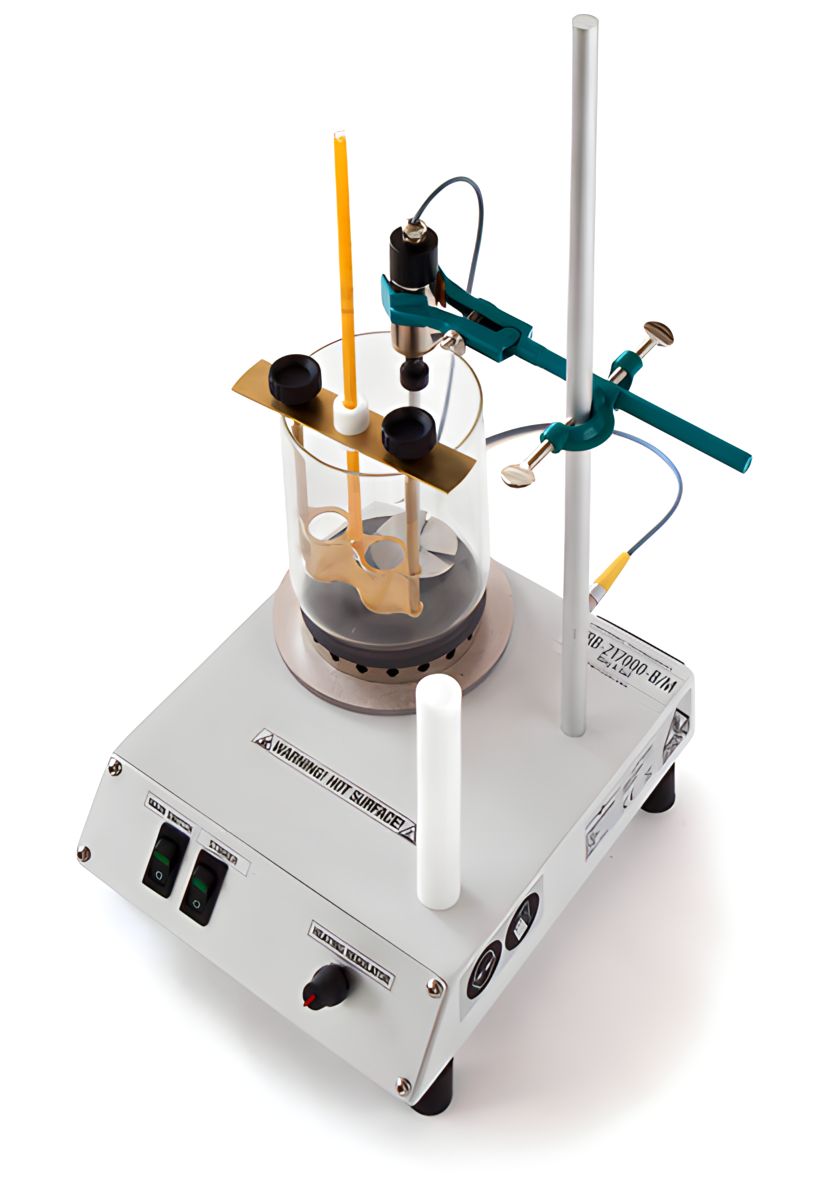

Softening Point of Bitumen (Ring and Ball Apparatus)

This test method covers the determination of the softening point of bitumen in the range from 30 to 157°C (86 to 315°F) using the ring and ball apparatus immersed in distilled water (30 to 80°C), USP glycerine (above 80 to 157°C), or ethylene glycol (30 to 110°C).

The Eco Coulometer with integrated magnetic stirrer and touch-sensitive display is ideal for water content determination in the 10 µg to 200 mg absolute water range. Predefined methods enable a smooth and easy instrument start-up. In addition to GLP-compliant printouts on paper or as PDFs, the Eco Coulometer also offers the option of being able to connect balances or send determination data to a PC via PC / LIMS reports. Indicator electrode and generator electrode without diaphragm are included in the scope of delivery. Coulometry is the ideal method for water content determination in the trace range in liquids, solids and gases. In addition, coulometry is an absolute method making titer determination unnecessary. When it comes to methods for water determination, Karl Fischer titration is the gold standard. Whether your matrix is chemicals, petrochemicals, plastics, or others – coulometric Karl Fischer titration is described by dozens of national and international norms and standards such as EN, ISO, ASTM, DIN, and others.

There are three main reasons, why this is so:

The compact Eco Titrator with integrated magnetic stirrer and touch-sensitive User Interface is ideal for routine analysis. It provides GLP-compliant results with minimum space requirements at all times.

The Eco Titrator Oil offers you the complete package for the determination of the acid or base number in petrochemical products. Included in the package are titrators and a 20 mL cylinder unit as well as a Solvotrode EasyClean, a robust, combined pH electrode specially developed for nonaqueous acid-base titration.

A SIMPLE AND RELIABLE ROUTINE You can save up to 120 titration methods on your Eco Titrator. Simply select the required method, enter the sample size, and press the start button – that’s it. The Eco Titrator performs the analysis fully automatically.

Analytical balances have a weighing capacity ranging from 62g to 320g and a minimum readability from 0.01mg to 0.1mg. They are widely used in government, university, and private company laboratories and quality control departments. They are also used for weighing reagents and samples, and measuring mass change and density in pretreatment processes before the use of analytical instruments. Specifically, they are used to weigh reagents and samples before analysis when using LC/HPLC, LC/MS, GC/MS, UV, thermal analyzers, and TOC analyzers.

Analytical balances have a weighing capacity ranging from 62g to 320g and a minimum readability from 0.01mg to 0.1mg. They are widely used in government, university, and private company laboratories and quality control departments. They are also used for weighing reagents and samples, and measuring mass change and density in pretreatment processes before the use of analytical instruments. Specifically, they are used to weigh reagents and samples before analysis when using LC/HPLC, LC/MS, GC/MS, UV, thermal analyzers, and TOC analyzers.

CE certified, these Digital Precise Refrigerated/Heating Bath Circulators possesses advanced refrigeration systems that ensures temperature performance as well as an innovative powerful circulation pump that ensures temperature uniformity.

Digital Muffle Furnaces are well-built with digital PID control system, patented jog-shuttle control system and digital LCD with back-light function. The 4-side heating mechanism ensure the short heat-up time and high temperature uniformity, and the maximum temperatures are 1,000℃ for FPX model and 1,200℃ for FHX model.

Labsys is there to guarantee the highest level of fume containment that is well able to eradicate all different types of gaseous contaminants so that the users do not breathe in hazardous air.

The flexible arm system of suction arms use friction joints and ball bearing for necessary grip and easy movement. Suction Arms can be fixed on wall/ceiling/worktop with adjustable arms and suction cup.

The flexible arm system of suction arms use friction joints and ball bearing for necessary grip and easy movement. Suction Arms can be fixed on wall/ceiling/worktop with adjustable arms and suction cup.